Current practice is to lubricate before sterilization, which poses a number of problems:

- “You can only sterilize what’s clean and dry”. If oil is introduced into a handpiece or motor before sterilization, this recommendation is not met.

- We’re all familiar with the incompatibility of oil and water: wherever there’s oil, there’s no water. And if there’s no water, there’s no sterility…

- During sterilization, during the various vacuum phases of the autoclave, the oil is sucked out of the handpiece or motor, reducing the amount of lubricant in the instrument.

- The little oil that remains creates an emulsion on contact with steam, which blackens the oil and amalgamates in the gears and bearings as they dry. On the block, handpieces or engines seize up, heat up and black emulsion flows over the work.

- Frequent repairs hamper block organization and cost too much.

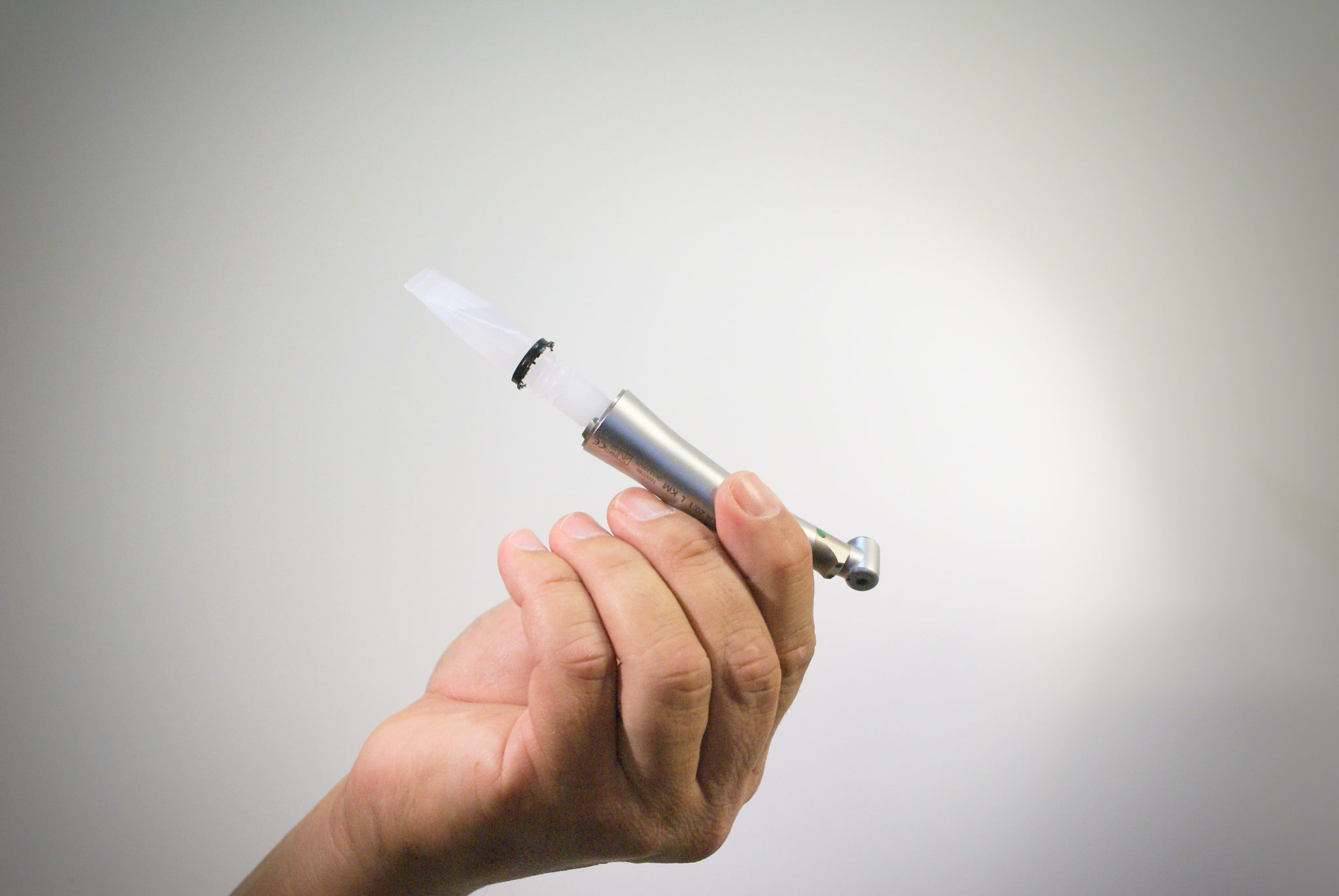

- Aware of the quantities of disposable plastic used in the medical sector, our product is 100% recyclable and made in France from 50% recycled polyethylene. STERILUB®️ is an innovative, eco-responsible product.